AH series

Cooler element, plate-fin heat exchanger, made up of superimposed aluminum, brazed in the furnace at controlled temperature around 600℃.

Maximum dynamic pressure :20 bar.

Maximum static pressure :30 bar.

Max. operating temperature:120℃ ( Disregarding the fan motor can stand for.)

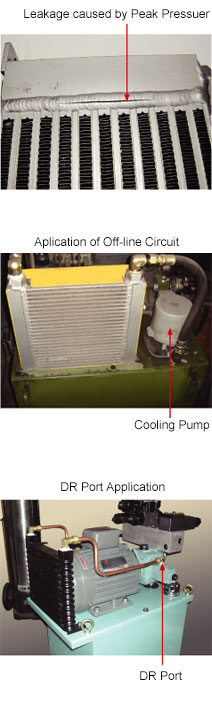

To preserve the heat exchanger, when installed on the return line of the system or when the equipment is started with cold oil, a by-pass valve should always be mounted in parallel to the exchanger in order to avoid excessive pressure surges.

An alternate piping method used a separate circuit from the reservoir with a small pimp to drive the oil through the heat exchanger.

Filters often are incorporated into these side circuits or kidney loops, as they are sometimes called.

For all applications, with the exception of oil cooling, it is recommended to consult our technical department.

AW series (plate-fin)

Suit for high setting pressure, variable displacement piston/vane pump drain, or separated cooling cycle.

AL series (stack layer)

This series do not withstand pressure peaks, can be used only where pressure peaking does not exist.

For hydraulic, must be for variable displacement vane pump, pump setting pressure under 70 bar, Drain only!

Installation & Maintenance

For correct installation of the exchanger, this must be supported by flexible components and connected to flexible tubing.

The exchanger should be installed in such a way that there should be no obstacles to the air flow, Normally particular attention should be paid to the cleaning of the cooler element and natural air exchange has to be guaranteed, in order to avoid a reduction in thermal efficiency.

Air Side Cleaning

Cleaning on the air side can be done using compressed air or water, directing the jet parallel to the fins so as not to damage the fins.

During this operation, the electric motor must be disconnected from the power supply and must be properly protected.